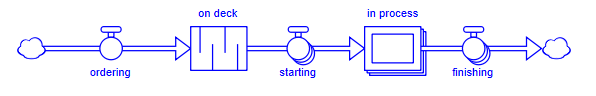

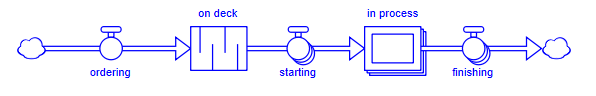

An oven represents a batch process in which material is collected for processing, gets processed for a prespecified amount of time, then is released from processing for use downstream. Ovens can only have a single inflow and a single outflow. Typically an oven inflow will come from a queue (see Queue Computation) and often the oven will be arrayed by processing dimension that the queue is not arrayed by (for example station):

The oven has four distinct states as returned by OSTATE builtin:

How long the oven holds material for processing. The time specified when the over starts processing is use after rounding to the nearest DT.

The amount of material the oven can hold. When this amount of material if in the oven it will start processing. This can be left blank to say that the oven can hold any amount of material and will start processing after the Fill Time has run out.

The time allowed to fill the oven before starting processing. This time is specified when the oven begins filling and is rounded to the nearest DT. If the oven reaches capacity before this time is till start processing, otherwise it will start processing when the fill time has been used. You can leave this blank to not constrain the amount of time for filling.

The time after processing that the oven should be left empty to prepare it for new material - this could be cleaning or workstation setup. During this time no new material will be accepted by the oven. The value of the clean time variable when the oven finishes processing is used and rounded to the nearest DT.

Provides an expression that, when true, will cause the oven to go into an arrested or paused state. When arrested no new material comes on or goes out, and no processing or cleaning gets done. The amount of time remaining to process, clean or fill the oven is not decremented while arrested.

When the oven starts with material in it you can specify the initial attribute and cycle time. See Initializing Discrete Stocks for more discussion.

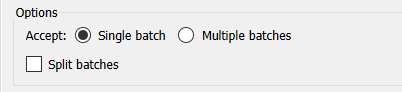

If an oven has a capacity that would be exceeded by the next available batch, the oven will not accept the batch unless split batches is checked (the default). If you do not want to allow batches to be split, you can uncheck that box:

When disallowing split batches be careful to either set a fill time, or have the queue leading to the oven have an overflow or purging outflow to prevent the oven from never starting its cook cycle. For example an inflow of 2 with an oven having a capacity of 3 will never get the oven to capacity.