It is possible to tag material going through flows in Stella models to keep track of an attribute associated with that material, and also the time the material ends up spending in downstream stocks. The ability to track such information is always available when the flows are connected to conveyors, queues and ovens, and is available for flows connected to non-negative stocks when you select Cycle Time as the integration method on the Model Settings Properties Panel.

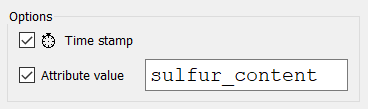

Both attributes and start time are set on flows that you choose. They are most commonly set on the first flow into a chain, but they can also be set (or reset if already set) on flows between stocks. The are set in the Flow options for the flows by time stamping the flow (![]() ) for cycle time and by providing an attribute equation to track the attribute. You can set neither, one or both of these.

) for cycle time and by providing an attribute equation to track the attribute. You can set neither, one or both of these.

Once these properties are set on the flow, they will be tracked on material passing through conveyors, queues, and ovens, as well as non-negative stocks with no biflow connections if cycle-time is selected as the integration method.

An attribute is simply a number that is associated with a flow. The number is specified by an equation that is computed when the flow occurs. That number then remains with the batch of material that the flow processed as it travels through downstream stocks.

For example, suppose that we tracking coal processing and sulfur content is measured on the coal as it is mined. By attaching this to coal as an attribute for downstream processing we can see the amount of sulfur in the coal when it is finally burned to determine what would be released from the combustion process. Attributes can be tracked using the discrete builtins ATTRCOUNT, ATTRMAX, ATTRMEAN, ATTRMIN, and ATTRSDDDEV (see Discrete builtins).

Attributes do not change once they have been set. The batch of material that is represented by the flow at a time (DT*flow_rate) will keep the attribute associated with it as it travels through downstream stocks and flows.

Cycle-time lets you generate and collect useful metrics about the amount of time that material spends "in process", or moving through a conserved flow chain. These metrics can be helpful in a lot of modeling contexts. Specifically, cycle-time metrics can be valuable when you're engaged in process re-engineering or process improvement. The clear, unambiguous cycle-time metrics the software gives you can help both to diagnose process problems and to test and evaluate any proposed alternatives.

The topics in this section tell you about cycle-time functionality. It's divided into three parts:

Cycle-Time Concepts gives an overview of the cycle-time concepts incorporated into the software.

Incorporating Cycle-Time into Models walks you through a simple process for putting cycle-time into a model. Along the way, this section gives an overview of the Builtin cycle-time functions.

Cycle-Time Rules details the "rules" of cycle-time, for a main chain with multiple flows and for a sub-model, with a brief discussion on the changes in internal calculations that happen when cycle-time is brought into play.

Each cycle-time Builtin function is documented in detail in Cycle-time builtins, in the Builtins section.